UTM

HULL SURVEY

MEASUREMENT SURVEY

- Special, Annual & Intermediate Surveys

- CAS and CAP Surveys

- Rafting Surveys

- Rope Access Survey

- Vessel Condition Surveys

- Steel Estimation and Dry Dock Specification Preparation

- Pit Gauging / Mapping

- Steel Inspectors / supervisors

- Steel Asst.Superintendent for Dry Docking

- Pipeline Inspection and Pipeline Gauging

ULTRASONIC SURVEY

- Aaina UltraMarine Services. hold approval certification from

- ABS, BV, DNV-GL, IRS, KRS, LRS, NKK, and RINA.

- All UltraMarine technicians have several years of experience and are qualified to internationally recognized standards

- All UTM surveys are covered, especially Class Renewal / Special, CAP and CAS.

- We use the latest Cygnus Ultrasonic Thickness Gauges Instruments

- Planning documents prepared if required.

- Reports are prepared onboard on laptops.

COATING SURVEY

- Identify the extent of coating breakdown areas with percentage of breakdown

- Identify type of coating failures: peeling, flaking, blistering,

- pitting/grooving, free edge breakdown and discolouration.

- Provide a square metre total of coating repairs.

- Give each tank a coating rating.

- Coating surveys can be done separately or as part of a hull condition survey.

VESSEL CONDITION SURVEY

HULL CONDITION / STEEL RENEWAL SURVEYS

UltraMarine Technicians have many years of experience and training on a widerange of vessels, especially Tankers, Bulk carriers, LNG, LPG and Container ships.

Report includes:

- Visual notes

- Ultrasonic gauging to confirm areas of wastage

- Photographs of general condition & specific defects

- Drawings of defects to show location & type

- Renewal / repair specifications, showing location, material grade, and

steel weight in Kg. - Modifications.

- Areas of Coating.

- Specifications can be sent to yards to get detailed tender, avoiding costly additions after entering the yard.

- Reports give a comprehensive picture of the vessel’s condition and are easy to understand. Kg.

Reports cover:

- Coating condition

- Steel condition

- Steel wastage above class allowable limits

- Mechanical damage

- Fractures

- Pitting & grooving

- Anodes, pipes, ladders and outfittings

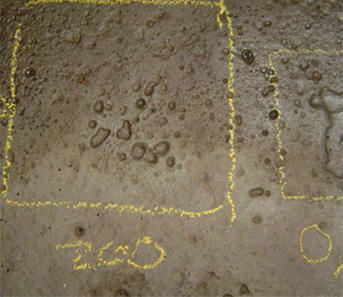

PITTING SURVEY

- Pits are a major concern as they can very quickly lead to a pollution incident if the problem areas are not identified and dealt with promptly.

- Pitting surveys map all pits/grooves.

- Pits are measured and marked in the tank and on a colour coded drawing to show exact location and depth.

- Where extensive general pitting is identified UltraMarine technicians can assess the residual mean thickness of the remaining structure by pit gauging, ultrasonic thickness measurement and visual experience.

HULL REPAIR SUPERVISION

- Without the owner’s representative on hand the quality of Hull Repairs cannot be assured. There can be a conflict of interest between the shipyards needing to get the job done quickly and cheaply but the owner wanting to get it right and out of the yard on time. With the current pressures on superintendents UltraMarine can be there to help achieve the owner’s objectives.

- Who better then to oversee hull repairs than the inspector who carried out the pre-docking survey and wrote the repair specification? Senior UltraMarine inspectors are available to follow up on survey work at the dry-dock, leaving the engineer superintendent to concentrate on other matters. The burden of production inspections and class surveys can be assumed by a UltraMarine inspector, along with P&I surveys, CAP surveys and any other inspection where an owner’s representative is necessary.

- Steel and coating departments demand a huge amount of time in terms of inspection and discussion. Specialist issues regarding acceptability of repairs, surface preparation and coating application can be readily addressed by UltraMarine supervisors with detailed knowledge of all relevant quality codes and standards. Common structural codes such as IACS SARQS (Shipbuilding and Repair Quality Standards), IACS Recommendation No.20 ‘Guide for Inspection of Ship’s Hull Welds’, welding codes from AWS (D1.1 Structural Welding Code), ASNT NDT Codes and painting / surface preparation codes from ISO, NACE, SSPC are all referred to.

- UltraMarine inspectors are able to give advice upon fatigue and corrosion related issues and provide detailed modification drawings for classification society approval. The inspector can refer to our wide knowledge to be able to make an informed decision on the correct type of repair. Getting the repair correct the first time will save a significant amount of time and money, reducing pollution risk and vessel off-hire time

PIPING SURVEY

- Piping surveys are conducted to inspect, document and track piping condition and history. International Inspection performs Ultrasonic (UT) and Visual testing services to make these evaluations. Ultrasonically with an “A Scan” presentation and dual element transducer a real time 100% scan of the piping will pick up internal pitting and erosion in areas that would not be accessible by other means. Visual Inspection (usually in a shipyard environment) is performed using lights, mirrors, bioscopes and other visual inspection devices when valves and inspection ports are removed.

- These UT surveys can be done through coating and with product in the line on most any type of Pipe line. Typical lines aboard a tanker for example would include the deck Cargo, IGS, COW, Ballast, Fire & Foam lines and in tank piping. The Record keeping is catered to the clients needs. In most cases the piping system is drawn in AutoCAD showing remaining wall thickness together with notable discrepancies. If requested these reports can also supply complete information on each and every piece through the systems including pipe schedule, size, dates rolled, repaired or replaced and this history could be tracked through the life of the vessel.

MARINE SURVEY

Marine Survey Division consists of well experienced surveyors using most modern equipments as per the assessment criteria required for both Hull and Machinery. We are expertise in different surveys listed below:

- Under Water Services (Diving Survey)

- Pre purchase Surveys

- Hull / Corrosion Survey

- Steel Renewal Surveys

- Load Line and Freeboard Calculation/ Surveys

- Deadweight / Draft Surveys Damage Surveys

- Hatch Leak Detector

- Anchor Chain Calibration

ABOUT EQUIPMENT

THICKNESS GAUGE EQUIPMENT

MULTIPLE ECHO ULTRASONIC DIGITAL THICKNESS GAUGE Measures metal thickness to determine wastage or corrosion – accurately, quickly and without removing surface coatings.

Primary New Features

- Light, rugged, small, shock-proof within IP65 sealed aluminum enclosure

- Gauge senses probe type and automatically adjust settings for optimum performance

- Hands free operation: belt/harness clip and neck strap included

- Display brightness automatically adjusts to suit ambient light conditions

- Simple keypad operation

- Protective silicone sleeve offers maximum protection and versatility

- The new Cygnus 2 is the smallest, lightest and most durable through coating thickness gauge available.

- Perfect for use on flat surfaces or pipes. Our multiple echo single crystal probe technology means you can measure through thick coatings and only the remaining metal thickness is displayed

Benefits of Cygnus Multiple Echo

-

- Measures remaining metal thickness on corroded and coated surface

- All measurements are error checked using 3 return echoes to give repeatable, reliable results

- Accepted by all major classification societies

- Greatly reduces inspection time and costs

- Echo strength indicator to aid measurement with multiple echo, readings are taken by Measuring the time delay between any three consecutive backwall echos.The time of T1(coating thickness) is ignored.

The times of T2 and T3 are equal to the time that it takes to travel through the metal. Only by looking at three echoes can the measurements be automatically verified (where T2 = T3).

CARGO HATCH LEAK DETECTOR

Sea water ingress is one of the major sources of damage to cargo resulting in expensive insurance claims. Cygnus Hatch Sure provides a quick and effective method of evaluating hatch seals.The system consists of a battery powered transmitter containing 19 ultrasound emitters (40 kHz).The emitters are arranged to produce an omni-directional sound field, uniformly distributed throughout the cargo hold.The receiver part of the system displays the sound energy level that passes through gaps in the enclosed cargo hold to enable the location of leaks to be quickly and accurately identified.