NDT

NDT ACTIVITIES

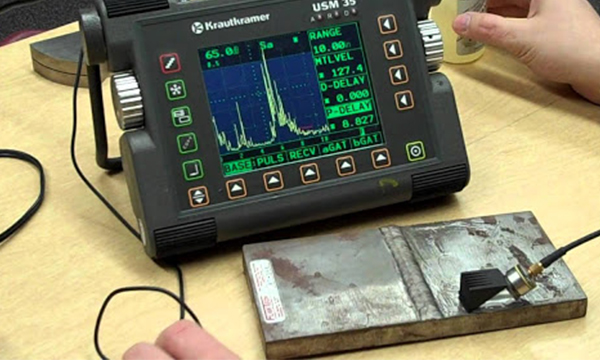

ULTRASONIC FLAW DETECTION

- Examination is carried out by using a pulse echo wave which is generated electrically. The use of an A scans presentation enables an immediate response to a signal received from a discontinuity within the item being examined. The electrical pulses are transformed into mechanical waves which can travel meters in fine grain materials.

- Typical equipment shall have calibrated attenuators with increments of 1 or 2 DB steps. The frequency ranges from 1 MHz to 5 MHz enabling us to examine various grain structured material. Automated ultrasonic techniques available.

- The simplest form of ultrasonic is for the measurement of thickness usually utilizing either a Kraut Kramer DMEDL or DMS or CYGNUS flaw detectors.

MAGNETIC PARTICLE INSPECTION

- Magnetic particle testing is a nondestructive test which will find surface and slight subsurface indications in ferromagnetic materials. Although widely used in lab and large production facilities International Inspection specializes in field inspections. While for most inspections a yoke is used there are also prods and coils that are used for certain applications.

- The dry powder method is the most employed for field inspection. It is a rapid, effective inspection technique and does not require any special lighting for evaluation.

- Wet visible and wet fluorescent methods use magnetic particles suspended in liquid. The visible method requires white light while the fluorescent method uses ultraviolet light for evaluation.

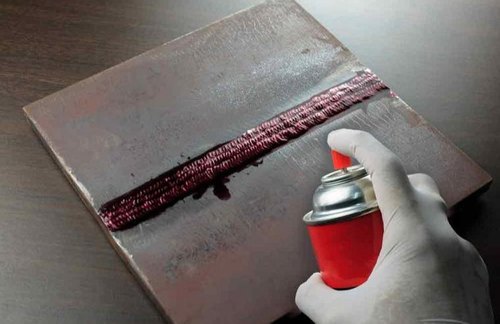

LIQUID PENETRANT TESTING

- Liquid penetrant testing is yet another form of nondestructive testing used for finding surface defects only. penetrant testing is a physical and chemical test used for detecting and making visible to the naked eye surface related discontinuities in non-porous materials.

- Solvent removable Penetrant is the most common application. Evaluation is made with White ambient light.

- corner Water washable Penetrant is a rapid and effective means of inspecting large areas or in locations where the solvent would have an injurious effect upon the material or personnel. The inspection is usually made with white light.

- Fluorescent Penetrant removable both by solvent or water and with evaluation made under ultraviolet light is the most sensitive of the Penetrant methods for inspection. A darkened environment is necessary for inspection under the black light.

RADIOGRAPHIC EXAMINATION

Portable field service is using modern Iridium 192 isotopes projectors. All field radiography units are equipped with darkrooms for on site film developing to give immediate results. Units are all operable on 12 volts, thereby precluding the need for external power hook-up.

Radiography has a wide range of applications, from weld defect evaluation to profile views used for locating corrosion and lockages. Radiography is also used to determine concrete contents prior to core drilling and sawcutting.

In-lab X-ray capability using 275-300 kvp/8-10 ma units and offering the following services:

- weld procedure tests and welder qualification test pieces.

- casting and components.

- weld procedure tests and welder qualification test pieces.

- Special needs: litigation items, personal interests, etc.

ULTRASONIC LEAK DETECTION INSPECTION

Ultrasonic inspection can be used in practically every phase of the maritime industry. There are application for marine vessels, dry docks, ship repair and shipbuilding.

Some of the major areas of inspection

- Bulkheads for water tightness integrity

- Hatch leak detection

- Vapor recovery system

- Condensers

- Steam systems (Valves, Traps, Gaskets, Deals, Boilers, Condensers)

- Pressure & Vacuum systems (Gas, Air, Nitrogen, etc)

- Motors, Pumps, Gears, Gear Boxes, Compressors (for internal wear)

- Dry dock usage not only includes all of the above, but also extremely large energy savings through compressed air leak detection.